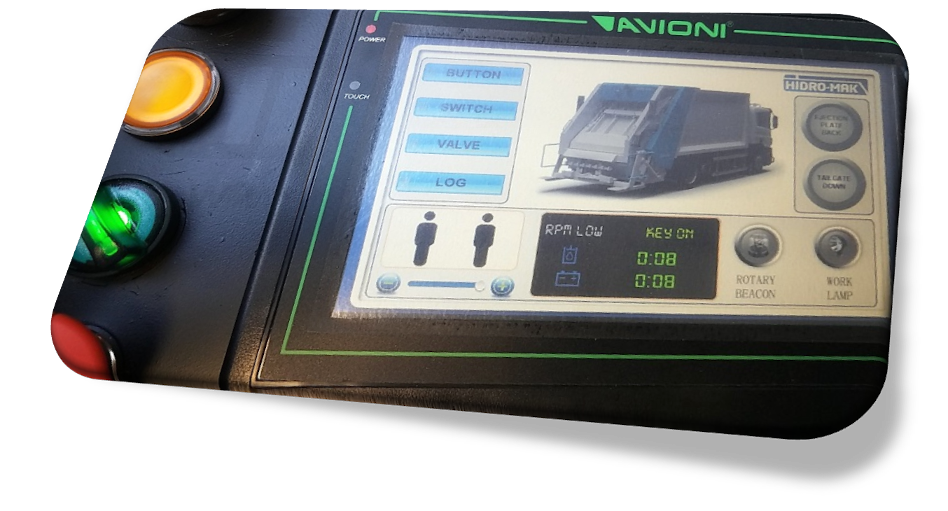

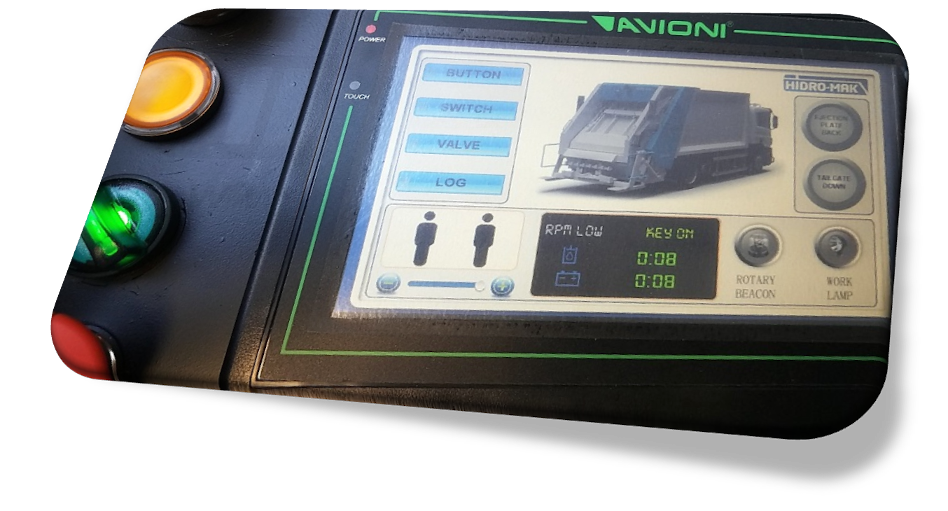

CAN-Bus Control System for Garbage Truck (Garbage Compactor), which is developed by

,

contains the following features (some features are optional):

-

Switching on/off beacon and work lamps, tracking status of the lamps by control panel.

-

Tracking status of PTO on the screen and saving total working time of the PTO.

-

Slide/Plate and bucket can be operated via the control panel, the number of compressions is saved, and the warning about lubrication can be displayed when the set number of compressions is reached.

-

The sliding curtain can be controlled via the control panel. The number of garbage unloading is saved, and the desired warning can be displayed when the set number of unloading is reached. Information that the scale is leading can be displayed on the screen.

-

Container lift control can be controlled via the control panel, the number of operations is saved, the desired warning can be displayed when the set number of lifting is reached.

-

The rear cover can be opened via the control panel, it can be displayed on the screen, and warning and / or blocking can be done if the driver wants to drive.

-

The compression system can be selected via the control panel as continuous mode, single mode, and the selection can be displayed on the screen.

-

When an error occurs in the system, it can be seen in which region the component is located.

-

Alarms from the system are saved.

-

It can be protected by the menus password reached via the monitor.

-

The oil filter pollution warning can be displayed and, if desired, operation can be stopped after a certain period of time.

-

The system pressure can be continuously displayed, warning when it reaches a certain value, system can stop after certain value.

-

The oil temperature can be continuously displayed, warning when reaching a certain value, the system may stop after a certain value.

-

The warning and / or system may stop when the oil level falls below the specified value.

-

When the maintenance flaps are opened, the system can be stopped and the cause can be displayed on the screen.

-

The warning given by the overload sensor to be placed on the axle can be displayed on the screen and the system can be stopped if requested.

-

Information can be displayed on the screen to indicate that the person is human on the stage, a signal can be sent to stop the vehicle, and a signal to reverse the maneuver can be sent.

-

If the system is cancelled while there is a man on the step, the system will restart with the penalty delay until the time when the PTO will be put into service again.

-

If there is an additional cover allowing automatic operation and if it is on, the system can be operated manually, these can be displayed on the screen.

-

All cables assembled on a central unit on the back cover will be transmitted to the body via a single line (thanks to CAN-Bus).

-

The body will also be transmitted via a single line to the control panel in the truck cabin in the second unit (thanks to CAN Bus).

-

Emergency stop buttons inside the cabin, front and rear, which can be displayed on the screen if it is pressed.